This post has been a couple of weeks in the ‘waiting’

Two weeks ago … my son was flying a short trip back from a local fly in when the engine slowed … it continued to slow and eventually stopped.

(The first thing to say .. is he exited from the upturned aircraft without a scratch)

What happened next is a testimony not only to his freshly acquired skills (a PPL of 12 months) but also to what he took in on the many hours of flying the biplane.

At 1500′ .. a stopped engine, even in a light floaty biplane doesn’t give you much think time. The very draggy nature of multiple wings and struts and wires and gangly springy undercarraige means you are going down .. and fairly quickly..although she does fly nicely at low low speeds …nevertheless.. NOT having the advantage of ‘increasing the noise and lift’ with your left hand must be somewhat disarming.

Its worth noting here .. that pretty much every time we fly the biplane we always put in some SLOW flying sequences … so CURRENCY on how she handles at very low speeds is something that is second nature… you also pickup the clues as to when you are approaching the stall .. the sound .. the feel of the controls …this aircraft most definitely benefits from its benign handling at super slow speeds and pretty much never drops a wing.

Will, managed the situation faultlessly. He was already talking with Norwich ATC so issued a Mayday call … they immediately halted all movements as he then advised of the situation.

Just NW of Norwich and with the village of Taverham getting larger in the windscreen he identified a field, initiated a downwind leg before establishing when to turn base and final and placed the aircraft in line with the planted corn crop and proceeded to descend on a final approach.

As indicated by the stuck Air Speed Indicators post the resulting stop… he was pretty much on the stall speed when the wheels impacted the 4′ standing crop.

(I’m guessing the ASIs are BOTH stuck as either a tube got pinched or the static got mud in it)

The resulting deceleration and capture of the undercarriage acted like an arrestor hook on a carrier.. bringing the aircraft to a fairly swift slow down .. before tipping up into its nose and finally flipping over onto its tail and a final resting 45 degrees inverted.

Having made the aircraft safe .. fuel and switches off he had to extricate himself from the upside down cockpit. I’ve heard stories of people surviving the crash only to pop their harness and fall 4′ inverted to the floor and break their necks !

Will found something to hold onto and popped the 4 way harness that had not let him move 1″ in the stop … and slipped out to the floor ..

He now called me .. who had been watching an ever slowing ground speed at home on flight radar .. wondering what was happening… and we set off.

Arriving to a village of blue lights and loads or people trying to see what was going on we made our way through the fire engines.. ambulances and police cars to the track that led up the side of the field… and proceeded to run across the field towards the group around the upturned aircraft.

Meeting Will and giving him a big hug I asked if he had been checked over and he hadn’t! So he walked over to the paramedics who checks him over and declared him fit !

The owner of the field, a local farmer, turned up and proceeded to discuss and plan how we might get her out.

The fire brigade stood down as it was slowly draining what fluids were left into the field… the paramedics stood down and that just left the Police .. this was their FIRST downed aircraft .. to take photos and liaise with the Air Accident Investigation Bureau AAIB .. who, after about 1 hour 45 approved us to move the aircraft

With the excellent assistance of a family from Priory Farm Aviators .. we collectively decided to strop the tailwheel and lift her vertically with a hoist the farmer kindly provided.

Once vertical.. on her nose cone… we pirouetted her around so that we could ease her down on the main gear

Once upright .. she was easier to move on her main wheels and we extrictaed from the field .. the crop lying down as the wheels went over and springing back up as we passed … so just leaving a ‘plane shaped hole in the middle of the field when we moved her.

On assessment… it looks like the airframe is all still square.. having checked base angles, measurements and brackets and rivets for movements. The engine also turns freely.

The deceleration of the corn and the general slow handling of the aircraft meant that any ‘sacrificial’ parts broke in preference to more major parts.

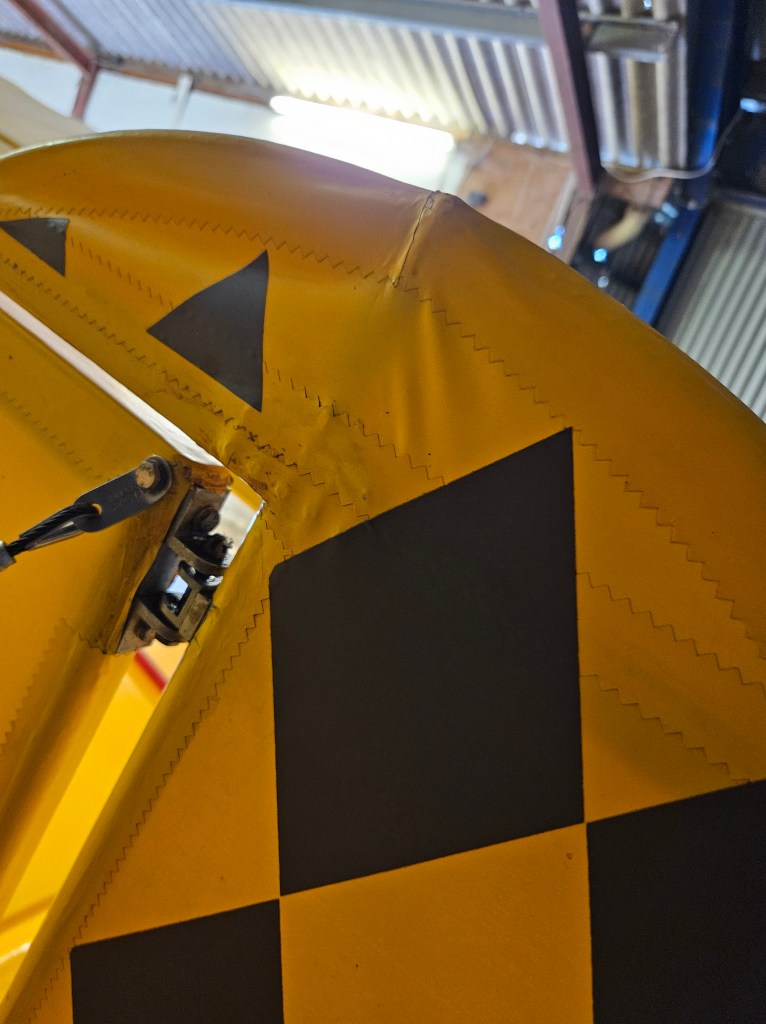

The wing pegs have alloy guide brackets which are bolted to the ply inboard ribs on the cabane … the ‘arrival’ and tip meant these took a rearward force that broke the ply and dissipated most of the energy

The lower wings, now on top, took no part in any impact ..it appears

That said, we have been cutting back the Oratex to expose and examine more and this will continue to confirm the list below.

- 2 new top wings – as roots crunched

- 1 new centre cabane as the 3 ribs that make this up have cracked

- 1 new prop .. although stationary it cracked on ground contact

- 1 new oil cooler matrix ..being the most forward part apart from prop this was squashed

- 1 new windscreen .. the only part Will technically broke exiting

CURRENT THOUGHTS ON WHY …

It has all the hallmarks of carb icing …no visible signs of engine stress … all fuel.lines and supply and pumps clean as a whistle… plugs all burning well

The inexorably slow run down also lends itself to that. I do have a carb heat block with a 2 stage element but it’s the type that you would probably have to have on for a couple of minutes before it became effective .. it doesn’t use exhaust flow like others so simply wouldn’t have had time to do anything.. Will did turn both on !

The engine will be removed (once allowed by insurers) for run out checks as well as general overall check.

… To be continued ….