Last week, saw the Jabiru engine coming out and being put in a car for its nip up to Yorkshire for ground checking

We still haven’t located a definitive reason for the inflight engine stop … and this trip was to strip down key parts to check for such.

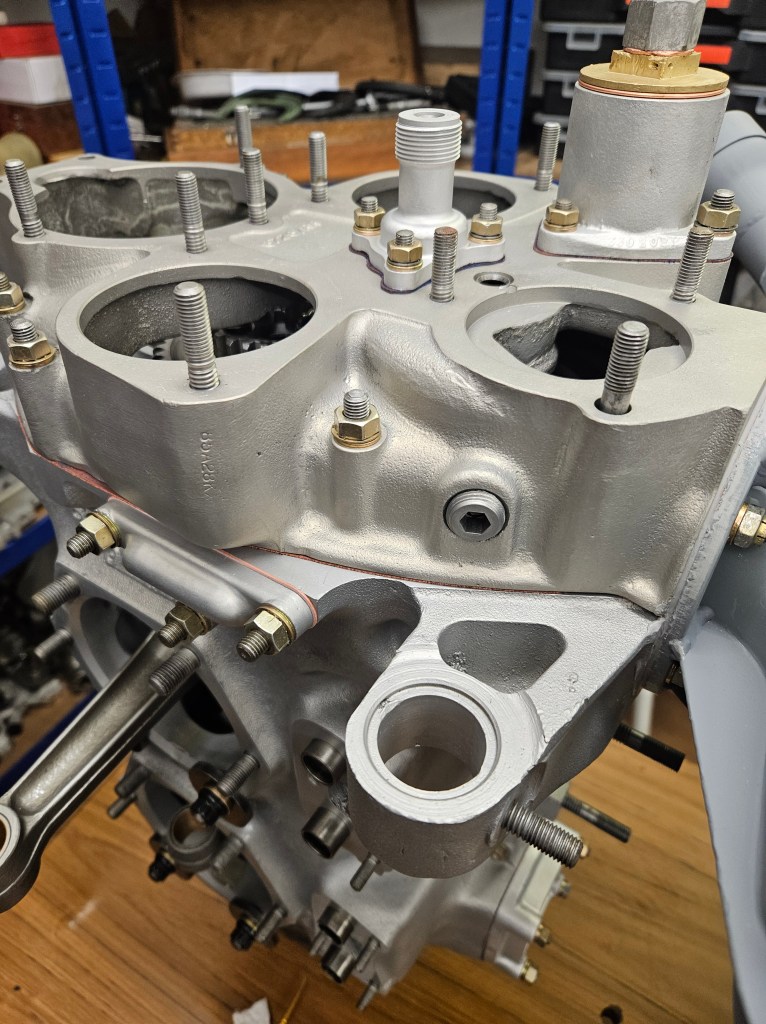

It is always good to spend a day with Kevin Hyam … at Beverley. His knowledge is vast and is a genuinely nice guy to work with. He had another chap working with him rebuilding a classic engine from every bolt upwards .. a positive work of art as the pictures show.

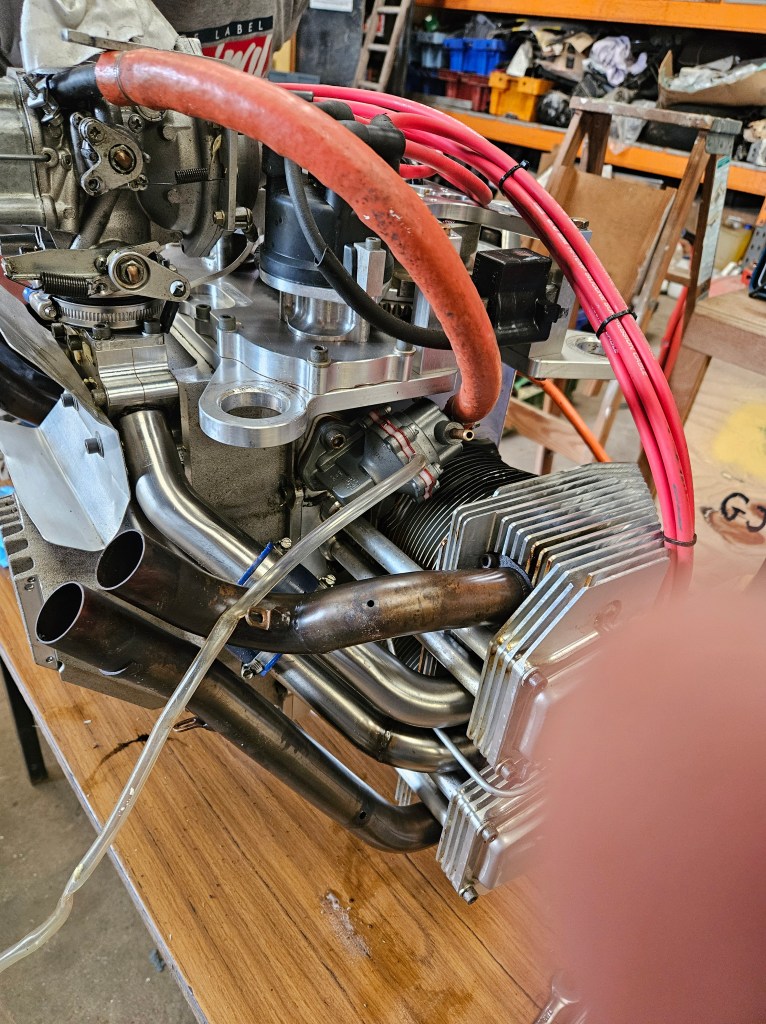

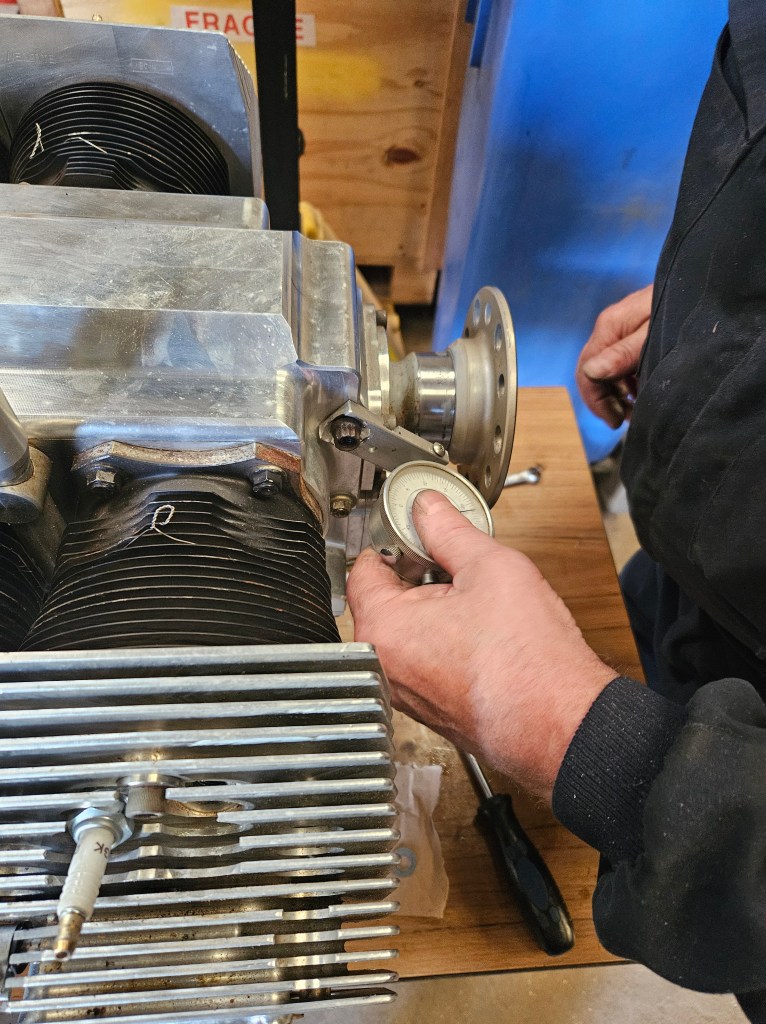

We mounted my Jabiru engine ‘nose down’ ..having had it supprted and strapped down in the back bucket seats of the BMW .. didnt quite fit in the boot ! ..We stripped a range of items down to check … all looked fine .. Kevin also removed the fuel pump and completely refurbished it adding a slightly softer spring to aid pressure. His neat tool for setting the diaphragm placement was really clever.

Valves and gaps were checked along with the entire ignition circuit

Some of he new parts that Kevin is engineering are really smart, not relying on the vagaries of foreign imports and bringing more and more under U.K. abased design, manufacturer and fit can only bode well !

Returning home with a ‘fit’ engine was a relief .. this engine is now destined for my sons rebuild Jabiru project

A few days later, I return to Priory to begin labelling all the existing firewall forward wires ahead of decoupling the mass.

The engine mount is a useful platform on which to locate and mount and secure cable runs. These all have to be clipped, marked and moved to clear the way for the engine cradle removal.

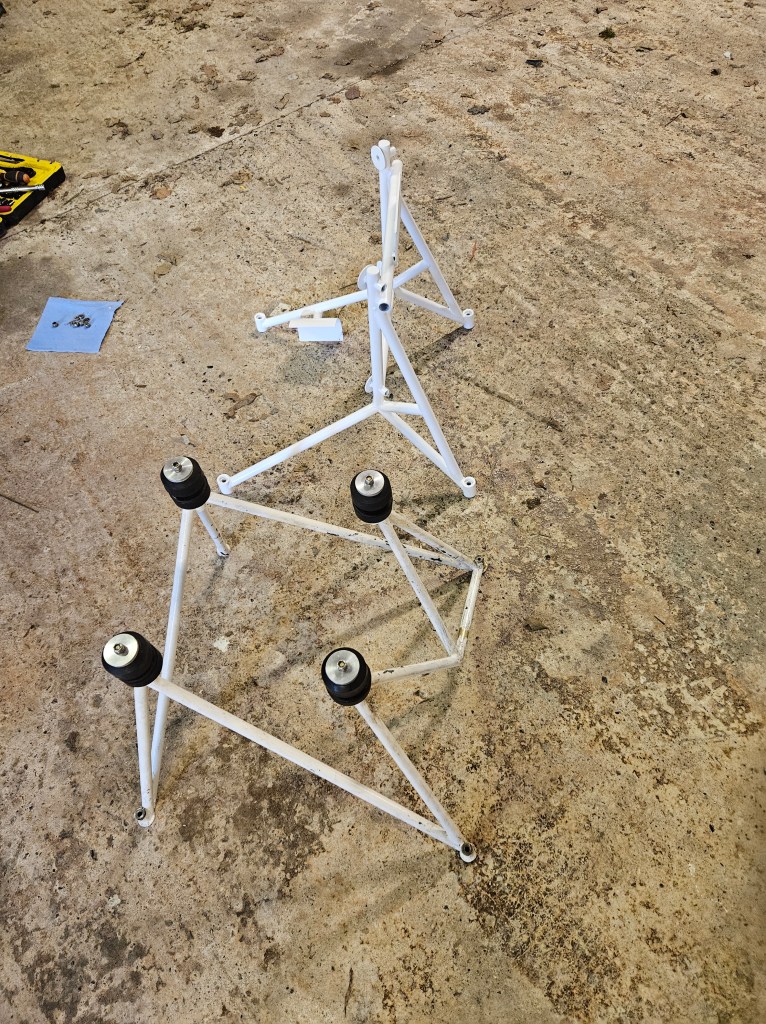

I still marvel at the relatively small 4 bolts that hold the engine mount in place. I seem to remember that the size of these bolts EACH have a sheer strength of something like 14,000kg !

The bolts duly removed … and after nearly 7 years since they were originally fitted …and the old frame simply slides off.

The new (Rotax) mount looks pretty sturdy compared to the old mount and slips easily into position.. ready to take the new shiny Rotax 912 ULS any day 😊