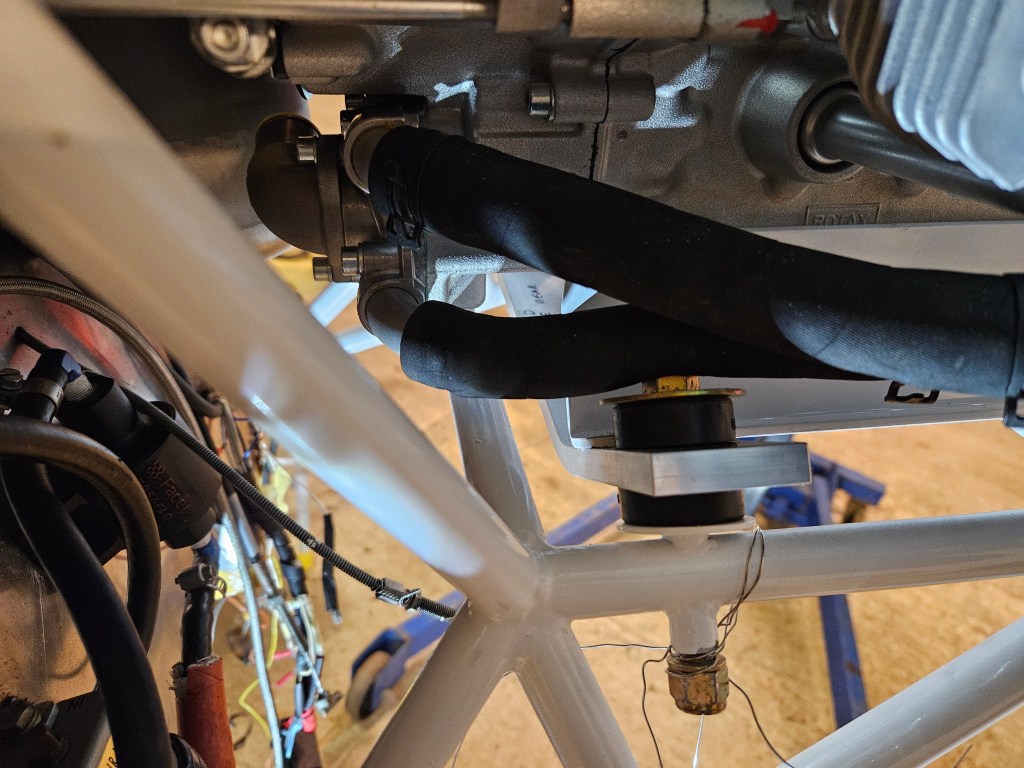

One of the things I’ve been concerned about is that the new Rotax 912 and new engine mount have meant that the coolant tubes run is too close to the engine mount bolts and the coolant exit pipes (that leave the water pump).need to angle slightly to ensure the coolant rubber tube misses these

A bit of research has identified how these pipes can be loosened and angled

“Adjusting Coolant Inlet Elbow

by John Smutny in 912 / 914 Technical Questions 3 years ago

Still struggling with the cooling system on a Kitfox IV w/ 912ULS.

In order to get the final hose installed from cylinder 4 to the water pump, I need to adjust 4’s cooling inlet fitting by about 10 degrees so it’s not pointing directly at the engine mount. There’s no way to install a hose without a kink in it otherwise. (Old hose had significant kink.)

Looking through the MM, I don’t see any text about removing or adjusting those fittings. There is a star next to them (page 336), but I find no correlating star in the text.

Going back a few pages to the water pump disassembly and reassembly, the same part numbers can be removed after heating to 180 degree F cleaned and re-assembled with a minimum of 5 turns and Loctite 243.

Is the procedure the same for the cylinder mounted elbows as the water pump? Am I missing something in the MM text?”