So, after a few ‘fettling’ sessions as they are known.. where you fine tune this and tweak that ..you reach a point and a day.. where aircraft, engine, weather and time all co align and you can carry out the flight test.

The Light Aviation Association (LAA), the governing body for homebuilt and other registered aircraft, have a plethora of forms and process that you need to follow on a regular basis to ensure your annual update is up to spec

Add into this the fact that yiu have had ‘an upset’ and this brings in additional checks and balances

All very sensible stuff to ensure you have ticked every box and thought of as many eventualities you can.

The ‘changes’ to my aircraft, post the incident, meant that I needed a full flight test. 14 pages of check items to run through.

I cut all these 14 pages into manageable half pages so that I could have them on my knee board in the cockpit and then attempt to capture all key information during the test flight.

The problem with lots of bits of paper in a small open cockpit is that its a bit blowy and tricky to keep your notes !

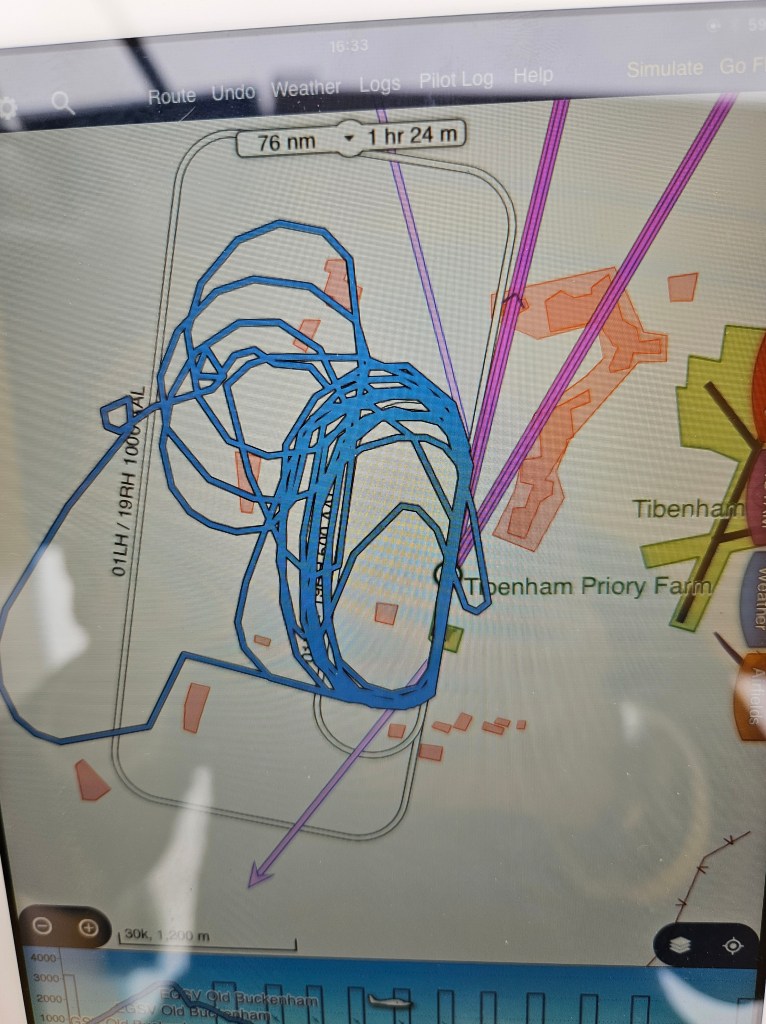

The initial power out climb was a very long slow orbit slowly climbing at a constant attitude for nearly 5 minutes.

The old overheating of the cylinders was pretty much gone and I timed each 500′ ad it went.. turning out to be about 600feet per minute

Once I reached 3,000′ it was getting quite chilly and so all temps were looking absolutely fine. I then captured all the vakue on the way up and then eased the throttle back and into a dive

The aim of the dive is to check VNE .. ie never exceed speed .. which is 100mph.

Leave a comment